The Anthony Gallo Story

the evolution of our range

|

|

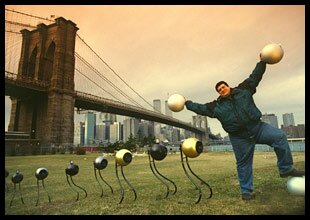

Gallo's heritage - In the beginningAnthony Gallo designed his first loudspeaker at the age of fourteen. His first commercially available product - the Nucleus reference speaker (right), went on sale in 1994. Today, his Nucleus Micro, A'Diva and Dué loudspeakers are sold in over 40 countries.  Anthony Gallo was born in 1963 and from an early age he had an interest in the sciences and would take apart just about everything he could get his hands on. At around age 13, he began to become hooked on loudspeaker design. His first experiments were with electrostatics at the tender age of 14! "Absolutely, I got shocked a zillion times, I was always awed by their transparency and purity. The dynamics however were always short of my expectations." |

Anthony then moved on to working with ribbons; "I took apart an old radar tube called a magnetron. A magnetron has about thirty pounds of Alnico V. After removing this huge magnet I started using it as the basic magnetic circuit for my ribbon designs". Once again he was hooked on their speed and transparency but "they were very hard to drive and limited in dynamic range, not to mention the myriad of cavitational resonances created by the pole pieces and various reflective distortions. By that point I was determined to continue on my search for the Holy Grail of tweeters. I started buying every dome available in the US but none even came close to satisfying me". Then, in the early 1980's an electronics magazine issued an article talking about the uses of Piezo film and the potential for audio applications. "I threw the magazine aside for a few years but in the back of my mind I knew that I would some day work with this material". In 1987 the first version of the CDT™ (cylindrical diaphragm transducer) was born. It took nine years of research and development to get the CDT™ to its current status. During that time Anthony worked for Panasonic where he was a commercial video engineer. He also started and ran a thriving video repair business, "I ended up selling the business along with my cars and everything else I owned to continue research on the Nucleus and various patent expenses." |

|

The Nucleus started out as a six piece system. "It took special movers to get it from one sound room to another". It utilised state-of-the-art wooden cabinet technologies (constrained layer damping, extensional damping, walls laminated in varying density sheets of lead and elastomer and had no parallel walls. Each channel weighed in at over 300 pounds)." I was told by several people in the industry that it was the best speaker they had ever heard, but that I would never sell any as it would have cost over $15,000 and this is not practical for a start-up company. I started trying to find a way to preserve the sound while saving money on the only component I could, the enclosure. The problem was coming up with an equally inert enclosure. It had to be either very, very massive, or incredibly rigid. It could not have any parallel walls and must minimise diffraction. These were my main criteria. Coincidentally, the enclosure with the best diffraction characteristics was also the strongest structure known, the sphere. I found that the speaker did not need mass and in fact the less mass used the better it sounded. Ironically enough, the 1.5 pound 12" diameter sphere that was used in the Nucleus blew away the 300 pound monolith in terms of transparency and lack of cabinet coloration". In 1993 when Anthony had sold off the last of his possessions Gary Pelled came along. Gary was a lighting engineer specialising in energy conservation via efficient lighting and design. He was working with the owner of a small facility in the Bronx. While discussing mutual hobbies with him, Gary mentioned that he liked audio equipment. The owner said "oh, you should go say hello to this guy in the back, he is renting some space from me and he builds speakers". Gary went to the back of the shop where he met Anthony for the first time. Anthony had the satellite portion of the old wooden Nucleus system hooked up and Gary was immediately awed by the sound. "I wanted to buy a pair and told Anthony that when he was ready I wanted one for a discount price. I knew right away that Anthony and I would become friends, we had the same hobbies and interests while growing up and most of all we both were entrepreneurs and honest, hard working guys". |

As the months passed Gary would call Anthony and offer him business and marketing advice when he called to see when his speakers would be ready. It became apparent one day that Anthony had run out of money to continue his research and bring the Nucleus to market. He told Gary that he had considered placing an advertisement looking for an investor. "I asked Anthony why he did not ask me to invest. He told me he that since I had my own business he didn't think I would be interested. I decided at that very moment that I would invest in this technology and devote half of my time to forming a speaker company with Anthony". Gary eventually had to give up his original business as Gallo Acoustics took over all of his time. As Gary tells it, the progression of events is summarised as follows: "We began by working together literally at the living room table. We listened to the behemoth Nucleus, which looked sort of like a Watt Puppy on steroids, and dreamed about ways to deliver what we were hearing to the world. It was around that time that we hit on the spherical concept. You know, you always hear stories about companies that start out in a garage or a basement, for us, it was a big deal when we were able to rent out the basement of Anthony's brownstone in Brooklyn, NY and just get out of the living room! We moved into the basement, mind you it is a 100+ year old building, and the dust down there was deep enough to ski on. There was also an old coal shoot, we liked that, and a boiler that broiled us all summer and put out enough fumes to do permanent damage all winter. This is one of those basements that have the hinged steel doors on the sidewalk. You had to open them up and climb down these steep mouldy steps just to get down there. Whatever was on the sidewalk, rain, snow etc., would seep into our lab, it was a real challenge. If you forgot to duck on the way down your head hit the steel trap door. In any case, we built some work benches and we were off building the first generation of Nucleus. It did not take long for us to gain critical acclaim for our sound at the Las Vegas Consumer Electronics Show (CES) and other trade shows. It did take time to get people to accept a large sphere in their living room. It was probably a year and a half down there before we rented a studio apartment around the corner. That was to become our offices, manufacturing, research and listening room space. Needless to say you had to move lots of boxes to find my desk, which was located in what used to be the kitchen. There was so little space that we had to store packaging at my apartment and make van trips whenever we ran out. It was there that we switched from the polyethylene cabinet to the spun aluminium one. We felt that we could gain market acceptance if the product looked ultra modern. If it had to be bizarre looking at least make it ultramodern so it had a chance. |

|

The idea worked and the Nucleus Reference and Solo models quickly ramped up to around 35-50 thousand dollars per month in sales. Two things happened at that time. One is that we made another move, to an empty garage in the neighbourhood that had five thousand square feet of floor space and some offices (there are still tire tracks leading up to the wall of the production and sound rooms we built in there). The other is that we met Don Fried, our financial backer and third partner. Don took the reigns as CEO and began giving us the guidance we needed to become a real consumer electronics manufacturing concern. It was not all rosy however, as the high end industry basically began to collapse. Home Cinema became the new buzz word and the dealers did not want to hear about another high end speaker that cost 2,500 or 4,000 dollars the pair (especially a big round one). We saw the change coming and continued to service the audiophile community and the hobbyist's world wide that sought out the Nucleus Solo and Reference with a passion. We also happened upon some various sized spheres from one of our vendors and decided to investigate an ultra compact home cinema system. It made sense to us to use all the tricks that we learned while pioneering spherical technology. Most notably the ability to get high output from small cabinets with no coloration. |

We came up with some prototypes and called Don in to New York to discuss strategy. He took one look at the Micro prototype and said "we are sitting on a fortune". The decision was made shortly thereafter to halt everything and focus all of our energy and resources on the Micro. We always knew we could bring back the expensive gear later. It also fulfilled Anthony's lifelong goal of a high end speaker that everyone could afford. I was happy to be making a speaker my friends could finally afford. As the Micro began to take off, we opened up the facility in Los Angeles. This gave us the ability to do research in Brooklyn and also ship to the East Coast from there. We could also take advantage of the good weather, inexpensive warehousing and extensive manufacturing base on the West Coast. In 1999 the Nucleus Micro was launched to great critical and commercial acclaim, the 'Micro' was joined by our flagship Dué speaker in 2002 and then by the 5" A'Diva in early 2003. |

|

Where our spherical technology came from... Then, in 1994, Anthony Gallo Acoustics changed the way we listen. Here was a speaker with a 12" diameter that weighed less than ten pounds, yet combined electrostatic purity with big-system volume capability. While reviewers have unanimously praised the Nucleus series as a breakthrough in speaker design, we're even more pleased with the reaction of the toughest critics of all - high end consumers. |

Since 1994, we've heard our speakers described as "breathtaking", "futuristic", and "strange." But whether you think our cosmetics are stunning or bizarre isn't really important to us. Everything we do is judged according to a single, simple goal - achieving the highest fidelity possible. It would have been much easier for us to design and build a traditional box-type enclosure with conventional drivers. But why would we? A number of fine companies already offer these products. We know how to build such speakers, and how to make them look beautiful, but they could never have delivered the type of performance we demanded. In our attempts to advance the state of the loudspeaker art, a fresh approach was needed. Despite their numerous shortcomings - low efficiency, large size, compromised bass and volume output - planar loudspeakers were long prized by audiophiles for their "boxless" sound. Therefore, our first challenge was to eliminate the two major causes of box coloration's, namely, enclosure resonance and baffle diffraction. Before we could define the future of loudspeaker design, we had to reach into the past. Back in the 1940's, Olsen realised that a spherical enclosure provided, by far, the most linear frequency response, the lowest diffraction and absolute elimination of resonance-generating internal standing waves. In order to deliver boxless sound from a dynamic driver, we eliminated the box. |

|

Why use a sphere? The Unknown Driver |

As described above, we have taken great pains to eliminate the sonic signature of the enclosure. Still, any cabinet - even ours - will generate some vibration. Therefore, our spherical bass module was not only designed to minimise resonance, but to prevent the remainder from interfering with the music. In a conventional enclosure design, resonances are controlled by bracing the interior, thickening the walls and adding damping materials. Unfortunately, these techniques also add mass. The cabinet stores this mechanical energy much like a capacitor stores an electrical charge, and releases them out of phase with the music signal. The inevitable result is a blurring of subtle details. By contrast, the Nucleus spherical bass module not only eliminates internal standing waves, but due to its ultra-light construction, reduces energy storage to insignificant levels. Compared with any other dynamic loudspeaker, the Nucleus series provides greater inter transient silence, and a more complete rendering of fine harmonic and tonal information. |

|

A new high in high frequencies With a surface area of 24 square inches, the CDTs' diaphragm has approximately the same output potential as 32 one-inch dome tweeters. But because our driver needs no voice coil or motor assembly, moving mass is negligible, providing unmatched transient response. Power handling is virtually unlimited, yet the driver is extremely efficient. And since this driver presents the amplifier with a purely capacitive load, it blocks low frequencies without the need for a crossover. Most importantly however, the CDT™ delivers ruler-flat frequency response from 2,500 Hz to beyond audibility across an unprecedented 330 degree axis of horizontal dispersion! Off-axis response remains identical to the on-axis measurement across the driver's entire radiation pattern. For the music lover, this nearly omnidirectional output means that perfect imaging is not limited to a small "sweet spot" directly between the speakers, but extends to the farthest reaches of the listening room. How does the CDT work? |

No crossover is the best crossover Through rigourous selection and treatment of the woofer, in conjunction with a tweeter which rejects low frequencies, Nucleus series loudspeakers deliver smooth, linear output without a crossover. In fact, only a short piece of high quality wire stands between each binding post and woofer solder tab - the simplest signal path possible! For the first time, the seamless purity of the best full-range electrostatics is available in a small, efficient and highly dynamic package. The Micro accomplishes this task with a similarly elegant solution. Utilising our patent pending S2 technology, the Micro can use only a single full range driver to cover the entire frequency range from 100 Hz up. This is the critical vocal range and the area where box designs and crossovers cause the most damage. Thus we have found an inexpensive way to create the same transparency and detail once available only with the CDT™ at much higher cost. We hope that you now have a better understanding of where the Micro came from and why it will outperform similarly sized conventional technologies. The Micro is capable of delivering very detailed and holographic sound, in a word realism. The Nucleus Micro maintains our high end heritage and utilises all we have learned during our first seven years of research and development. |